Choosing the right chiller location is not always as straightforward as it seems. While outdoor chillers are exposed to the elements, indoor units often face greater environmental strain from warehouse heat, restricted airflow and airborne debris. Whether new or used, the right decision depends on your system requirements, site conditions and long-term maintenance strategy. Understanding the trade-offs between the two can help you avoid costly mistakes and keep your cooling system operating at its best.

At Evolution Cooling, we support clients in making informed decisions about chiller placement, servicing and repairs.

Understanding the Key Differences Between Indoor and Outdoor Chillers

Indoor and outdoor chillers serve the same purpose, but the conditions they operate in are fundamentally different. Each brings its own set of installation, performance and maintenance considerations.

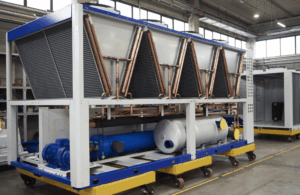

Indoor chillers are typically found in plant rooms, warehouses or service corridors. They rely on a well-designed ventilation system to reject heat and keep components within safe operating limits. Outdoor chillers are installed in open-air environments, such as rooftops or service yards. These units are engineered to withstand a wide range of temperatures and weather conditions.

The decision to go indoor or outdoor depends not only on available space but also on building layout, cooling demand and how much control you have over the surrounding environment.

Pros and Cons of Indoor Chillers

Indoor chillers are often preferred in facilities where exposure to weather is a concern or where noise reduction is important. Keeping the unit indoors can reduce wear from frost or UV damage and may offer easier access for engineers.

Higher Ambient Temperatures and Dust

The trade-off is that indoor chillers frequently operate in hotter, dustier spaces. Warehouses, production areas and mezzanines can introduce airborne particles that clog filters and coat condenser coils. Without proper ventilation, the heat rejected by the chiller recirculates into the same space, further raising ambient temperature and system pressure.

Increased Maintenance Requirements

These conditions mean indoor chillers generally require more frequent maintenance. Coil cleaning, airflow checks and inspection of surrounding ductwork are essential to prevent high-pressure faults or shutdowns. If airflow is restricted or coils are dirty, the chiller will struggle to reject heat efficiently, placing additional strain on the compressor and electrical components.

Pros and Cons of Outdoor Chillers

Outdoor chillers are common in commercial buildings, data centres and industrial plants. By locating the unit outside, operators often benefit from improved airflow, easier heat rejection and reclaimed floor space inside the building.

Environmental Exposure

However, the weather cannot be ignored. Outdoor chillers face year-round exposure to rain, wind, humidity and temperature swings. Seasonal maintenance becomes even more important, particularly in checking for corrosion, testing fans and confirming protection against freezing in colder months.

Better Heat Dissipation

One of the clear advantages is that outdoor chillers are rarely affected by recirculating hot air. With unrestricted airflow and cooler ambient temperatures, they often perform more efficiently under load. Still, placement matters. Units too close to walls or in poorly ventilated corners may experience heat build-up or airflow imbalance.

Choosing Based on Application

There is no one-size-fits-all answer to the indoor versus outdoor chiller debate. Instead, the best option depends on your specific cooling needs and site constraints.

Warehouses and Distribution Centres

Many operators place chillers indoors for convenience, but this often leads to poor performance over time. Dust, forklift traffic and high ceilings trap heat and contamination. For these environments, external chillers with appropriate screening and regular cleaning schedules are usually more reliable.

Laboratories and Medical Facilities

Cleanrooms and labs prioritise hygiene and temperature control. Indoor chillers may be essential in such environments, but must be isolated from production zones and supported with good air handling systems. Maintenance needs are higher, and filtration must be closely monitored.

Retail and Office Buildings

Outdoor rooftop chillers are common in retail and commercial premises, particularly where internal space is limited. These units reduce indoor noise and simplify plant room design, but must be protected from weather extremes and maintained regularly to prevent fan, coil or refrigerant issues.

Data Centres and Critical Systems

In high-dependency applications, such as data centres, a hybrid approach may be used. Chillers are often placed outside with supporting pumps or buffer tanks installed indoors. This separation improves reliability and resilience while reducing indoor heat load.

Let Evolution Cooling Help You Make the Right Choice

Selecting the right chiller location is just the first step. To get the most from your system, you need a chiller maintenance plan that matches the environment. At Evolution Cooling, we provide servicing and support for all chiller types, whether installed indoors or out. Contact us and let us help you choose with confidence and keep your cooling running reliably year-round.