When planning a cooling system, one of the most important questions is whether to install a single large chiller or to split demand across two smaller machines. Both options have their merits and the right choice depends on your processes, operating environment and long-term goals. At Evolution Cooling, we guide clients through this decision every day, whether they are investing in brand-new chiller units, reconditioned systems or temporary hire solutions.

Understanding the trade-offs will help owners and managers alike balance reliability, efficiency and cost in a way that protects their businesses for the long run.

The Benefits of One Large Chiller Unit

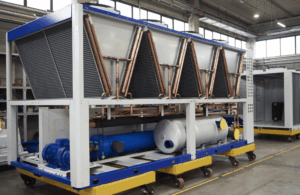

A single large chiller unit often appeals to operators who want simplicity and a straightforward installation. With one machine, there is only one control system, one set of pumps and pipework and fewer components to maintain. This can reduce initial installation costs and simplify servicing.

Larger chillers also tend to achieve high full-load efficiency. When the system is running at or near its design point, the energy performance per kilowatt of cooling can be excellent. For sites with consistent loads and little seasonal variation, such as large factories or centralised HVAC systems in office complexes, a single large unit can deliver reliable, predictable results.

There are practical advantages too. One machine requires less plant space and in some situations, installing one high-capacity chiller is the only option due to site layout or access constraints.

The Benefits of Two Smaller Chiller Units

Splitting demand between two chillers provides flexibility. Instead of one machine running constantly, the system can stage capacity by bringing a second unit online only when demand rises. This reduces wear, avoids short cycling and keeps part-load efficiency high.

Redundancy is another major advantage. If one machine fails or requires servicing, the other can continue running, maintaining at least partial cooling capacity. In critical environments where downtime is unacceptable, this resilience can be invaluable.

From a lifecycle perspective, two smaller units can often outlast one larger chiller because the load is shared more evenly. With staged operation, neither machine is under constant strain, which helps extend service intervals and reduce the risk of early component failure.

Real-World Applications

In high-precision environments such as laboratories, printing facilities or laser operations, redundancy and stability are essential. For instance, laser chiller units often need extremely tight temperature control to protect sensitive equipment. Using two smaller chillers allows operators to split demand and guarantee stable performance, even if one machine is offline.

Food and beverage facilities face similar pressures. Dairy chiller units, for example, are frequently installed in pairs to provide uninterrupted cooling during pasteurisation or milk storage. In these settings, even a brief failure could lead to spoilage and wasted production runs.

Other industries show different preferences. In the automotive sector, large-capacity chillers are common for paint shops and continuous production lines where steady, high-load cooling is required. In plastics, modular approaches are more popular, with multiple smaller machines allowing operators to adapt to fluctuating moulding schedules.

These examples underline that there is no single correct answer. The choice depends on process stability, tolerance for downtime and whether flexibility or simplicity matters more.

Factoring In Costs And Options

Cost is naturally a major factor in decision-making. A single large chiller may be cheaper to install and maintain initially, but two smaller units can reduce long-term risks and improve resilience.

If capital is a barrier, alternatives exist. Professionally refurbished systems can provide dependable performance at a lower entry price. Short-term chiller unit hire is also available if you need a stopgap after a breakdown or additional capacity for seasonal peaks. These options give you flexibility without locking you into the wrong long-term system.

To make an informed choice, it helps to profile your load accurately. Our chiller unit Capacity Calculator is a practical starting point for understanding your site’s demand and planning accordingly.

Choosing The Right Path With Evolution Cooling

A well-installed large chiller can last 15 to 20 years, but only with regular care. Two smaller units may provide redundancy, but both still require servicing to ensure efficiency and reliability.

At Evolution Cooling, we provide full chiller unit maintenance, servicing and repairs for all major makes and models. From coil cleaning to load monitoring, we ensure your system runs within design limits and continues to deliver stable performance.

Whether you lean toward one large chiller or two smaller units, the decision should be based on evidence, not guesswork. Site layout, cooling demand, energy priorities and tolerance for downtime all play a part. If you are weighing your options, contact us for straightforward advice and practical recommendations.