In plastic injection moulding, temperature control is central to ensuring dimensional accuracy, surface quality and cycle efficiency. The right chiller system does not simply prevent overheating: it plays a vital role in maintaining part consistency, protecting equipment and supporting continuous production with minimal variation.

At Evolution Cooling, we engineer bespoke chiller systems for the injection moulding sector, built around each client’s machinery, materials and factory layout. Whether you operate a single-cell moulding machine or a multi-line facility, your chiller must match not only the thermal load but also the wider system dynamics.

The Vital Role of Chillers in Plastic Injection Moulding

Injection moulding processes involve two distinct cooling demands. First is the need for process cooling, which typically serves hydraulic circuits, oil systems and return lines on the machine itself. Second is mould cooling, which regulates the temperature of the tool and its cavities to control how quickly the plastic sets.

Both systems work together to ensure smooth, uninterrupted operation. Inadequate or inconsistent cooling can lead to warped parts, flashing, shrinkage or brittle finishes. High oil temperatures may trigger alarms or cause long-term wear on hydraulic systems, while mould tools operating outside of optimal setpoints result in slower cycles and lower output.

Understanding Your Cooling Requirements

Every moulding operation presents a unique thermal profile. The size of the shot, the type of polymer used and the mould tool design all affect the amount of heat that must be removed per cycle.

For example, high-speed thin-wall applications may require aggressive cooling with stable, low supply temperatures to maintain tight tolerances. Engineering plastics such as PEEK or ABS often need a more controlled cooling rate to prevent internal stress. Meanwhile, multi-cavity tools demand high flow rates with even distribution to avoid cavity imbalances and uneven shrinkage.

A system designed without these nuances in mind can underperform or introduce new inefficiencies. That is why specifying a chiller based solely on cooling capacity is rarely sufficient.

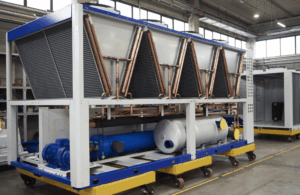

Air-Cooled vs Water-Cooled Chillers for Moulding

Most injection moulding applications use air-cooled chillers due to their ease of installation, self-contained design and low water usage. They are ideal for sites without access to mains water or where water costs are a concern. However, air-cooled units require good ventilation and may be more sensitive to ambient temperature changes, especially in hot factory environments.

Water-cooled chillers tend to be more compact and efficient in higher-throughput operations. When paired with a cooling tower or adiabatic cooler, they offer stable temperature control and better performance under heavy load. These systems require more infrastructure but are often preferred in larger facilities where tight process stability is critical and internal space is limited.

Integrating Chillers Into the Full System

Cooling in an injection moulding environment is not a standalone function. It must integrate with buffer tanks, pumps, flow meters, filters and temperature control units (TCUs) to maintain stable circulation throughout the plant.

At Evolution Cooling, we supply full turnkey systems that connect chillers to each machine or process line. This ensures optimal flow, redundancy and temperature control. For example, where multiple machines operate at different mould temperatures, we can zone systems or include multiple circuits within the same chiller.

Proper design also includes filtration to protect tooling from particulates, bypass circuits for energy efficiency and alarm integration for fast fault response. Without this system-level thinking, even the best chiller will struggle to deliver consistent results.

Choosing the Right Control Strategy

Modern industrial chillers come with advanced control systems that regulate pressure, flow rate and setpoints automatically. This allows real-time adjustment based on production demand, ambient conditions or specific polymer requirements.

For operations with high uptime targets, features such as auto-diagnostics, load balancing and inverter-controlled compressors help reduce energy use and alert operators to performance drift. These features are especially useful in plants with variable workloads or around-the-clock operation.

Custom Cooling Solutions From Evolution Cooling

No two moulding environments are identical. That is why our team designs each chiller installation based on your machines, process temperatures, production hours and future growth plans.

We also understand that downtime is costly in plastic manufacturing. Our 24/7 callout support and preventive maintenance services help minimise disruption and extend the life of your cooling assets. Every installation includes detailed commissioning, performance checks and operator guidance to ensure long-term efficiency.

Final Considerations for Long-Term Performance

When selecting a chiller for plastic injection moulding, consider more than initial capital cost. Factors such as servicing access, spare part availability, compressor type and energy consumption all contribute to the system’s total cost of ownership.

Partnering with a specialist like Evolution Cooling ensures your equipment does not just meet your current load, but adapts to production changes and continues to operate efficiently under real-world conditions. Contact us today to discuss a solution built around your plastic manufacturing processes.